Project name: DisFri – Friction Stir and Laser Beam Welding processes used in advanced joining of dissimilar materials

Research group: Manufacturing and Industrial Management

Nome do projeto: DisFri – Friction Stir and Laser Beam Welding processes used in advanced joining of dissimilar materials

Código do projeto: PTDC/EME-EME/29340/2017

Parceiros: IDMEC (Coord), INEGI

Financiamento: FCT, Lisboa2020, Portugal2020, EU

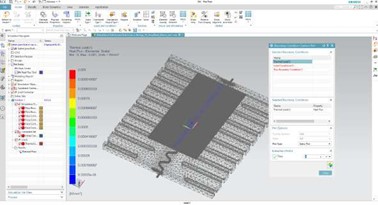

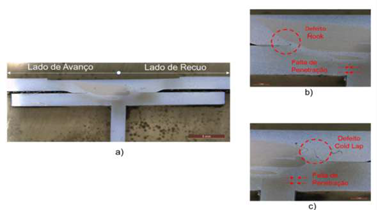

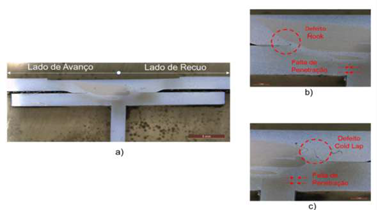

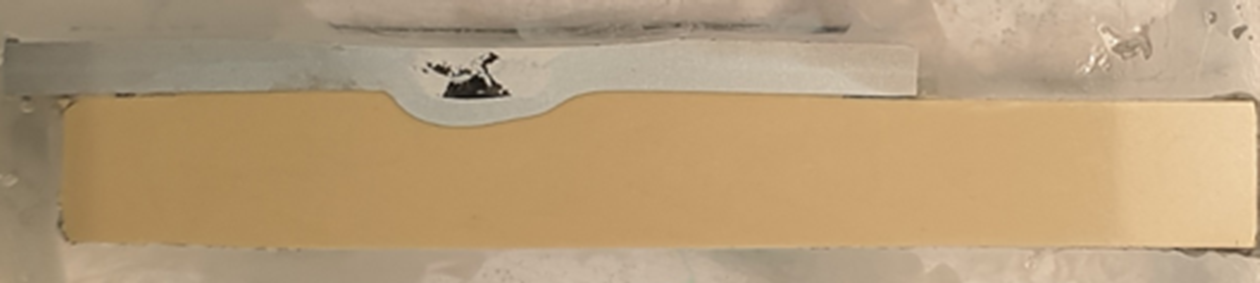

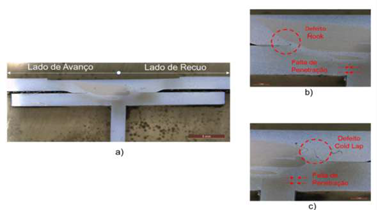

Descrição: The DisFri project aims at the development of technological solutions for dissimilar materials (composite/ aluminium and titanium/aluminium) joining on aerospace industry structures applying advanced mechanical welding technologies. The joining processes selected are two important breakthrough welding technologies: Friction Stir Welding (FSW) and Laser Beam Welding (LBW). Deliverables will include technological procedure guidelines, modelling of the most significant physical and metallurgical features and a detail investigation of the mechanical behaviour of the resultant dissimilar structures.

Joining of dissimilar structures or parts with tailor-engineered properties, in provision of the aerospace industry, is still a challenge concerning the achievement of sound joint quality and high productivity for cost-efficient manufacturing. Technologies currently established to join dissimilar structures are either too expensive, limited in performance or environmentally detrimental.

Dissimilar materials products, consisting of two or more different materials, have a very broad range of applications in our everyday world because they combine various properties such as strength and heat resistance, corrosion resistance, wear resistance, and/or low electric properties. FSW and LBW are mechanical processes delivering high quality assurance when technological conditions are correctly set-up. These welding processes are clean, ecological, do not depend on operator skills and produce weld seams of the highest quality, while they offer further advantage of being suitable for joining dissimilar materials that were previously impossible to weld by fusion methods.

Aerospace sector is experiencing a period of remarkable expansion and is expected to maintain and even increase its growth rate over the coming decades. It is known that welding can provide cost savings of up to 30% and weight savings of up to 10% for a typical airframe structure by replacing the actual mechanical fastening of subcomponents used to produce most of the primary structural components in airframe. The development and application of FSW and LBW technologies in dissimilar structures in the aerospace industry provide an effective tool of achieving superior joint integrity especially where reliability and damage tolerance are of major concerns. Since the aerospace components are inevitably subjected to dynamic or cyclic stresses in service, the fatigue properties of the welded joints must be properly evaluated to ensure the safety and longevity. The research team will develop for the first time a scientific project concerning the connection of composite/aluminium and titanium/aluminium structures.

Contacts: Virgínia Infante (virginia.infante@tecnico.ulisboa.pt)